Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 25 abril 2025

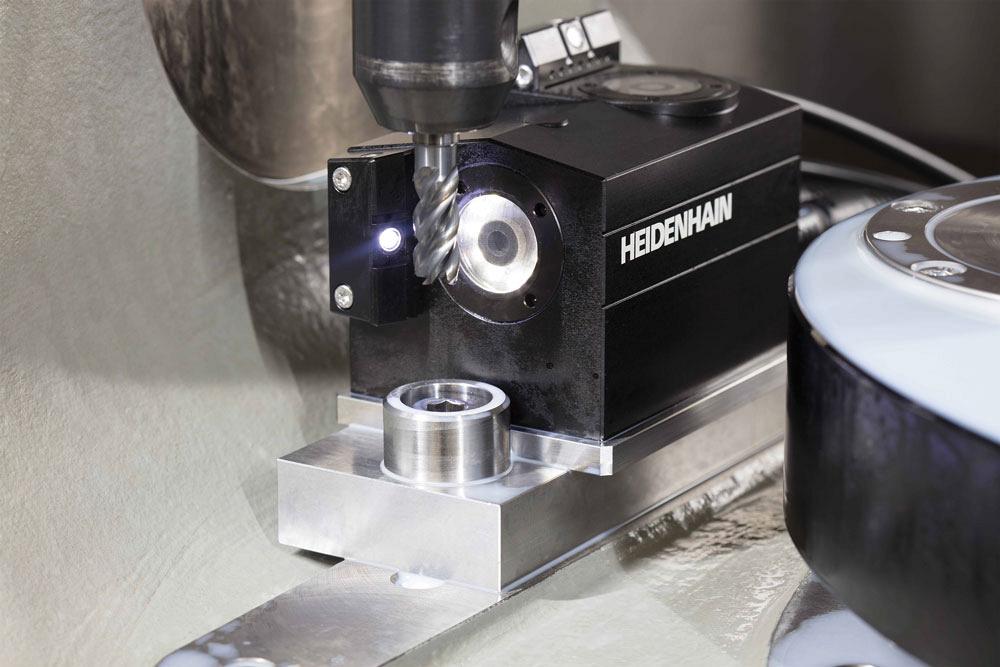

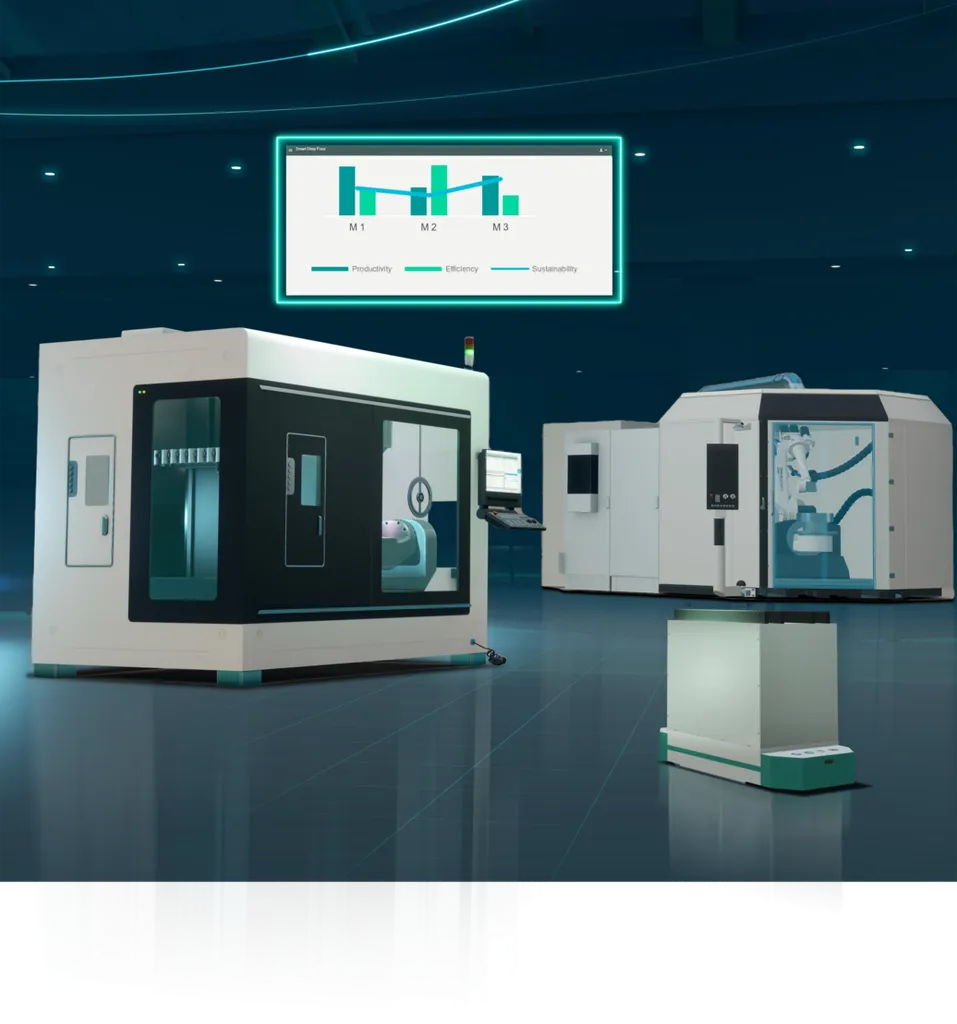

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

Vision Sensors in Factory Automation - Tech Briefs

A critical review for machining positioning based on computer

Print Inspection System, Surface Inspection System

Towards computer vision feedback for enhanced CNC machining

What is next for 5-axis CNC technology?

Additive Manufacturing Is Subtractive, Too: How CNC Machining

Machine learning and artificial intelligence in CNC machine tools

Siemens Xcelerator: Increasing productivity and sustainability in

Arc1Cnc

Recomendado para você

-

G1 Customs25 abril 2025

-

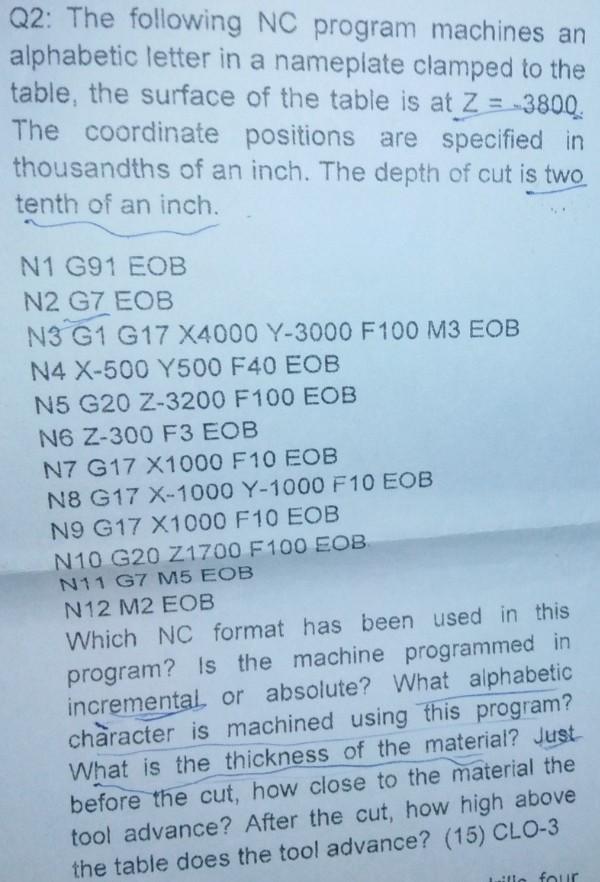

Solved Q2: The following NC program machines an alphabetic25 abril 2025

-

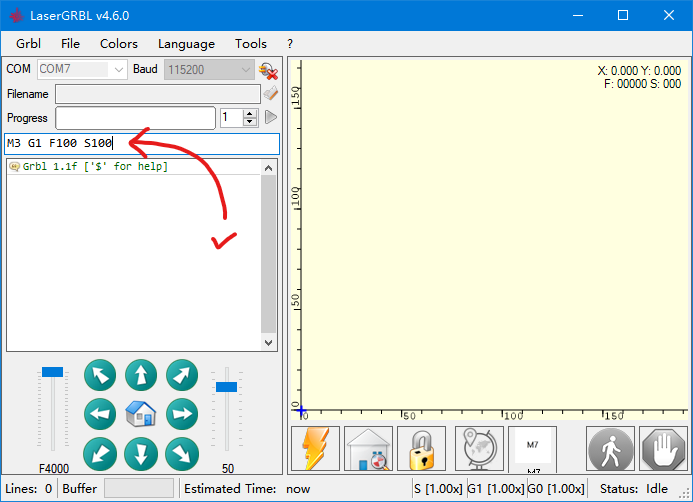

How to Test Laser at GRBL – NEJE25 abril 2025

How to Test Laser at GRBL – NEJE25 abril 2025 -

About - Hudlow Axle25 abril 2025

About - Hudlow Axle25 abril 2025 -

Used ABB Robot HGR Industrial Surplus25 abril 2025

-

WOWOW 9.2 in. Commercial Deck Mounted High-arc Brass Glass Filler25 abril 2025

WOWOW 9.2 in. Commercial Deck Mounted High-arc Brass Glass Filler25 abril 2025 -

49 Ford F1 #120 * Green * 2020 Hot Wheels * USA Case F * G125 abril 2025

49 Ford F1 #120 * Green * 2020 Hot Wheels * USA Case F * G125 abril 2025 -

19.5V 2.31A Notebook Ac Adapter Charger for HP 256 G3 G4 240 G4 G525 abril 2025

19.5V 2.31A Notebook Ac Adapter Charger for HP 256 G3 G4 240 G4 G525 abril 2025 -

100pcslot high quality adhesive sticker for LG Seal Label Sticker For LG F100 F180 F200 G1 G2 Nexus Package Box Sealing Strip25 abril 2025

100pcslot high quality adhesive sticker for LG Seal Label Sticker For LG F100 F180 F200 G1 G2 Nexus Package Box Sealing Strip25 abril 2025 -

node.js - In Javascript, the same input data is only different in25 abril 2025

node.js - In Javascript, the same input data is only different in25 abril 2025

você pode gostar

-

Samurai X - The Motion Picture (Rurouni Kenshin) [DVD25 abril 2025

Samurai X - The Motion Picture (Rurouni Kenshin) [DVD25 abril 2025 -

Mapa interativo de Elden Ring mostra localização de itens, NPCs, pontos de interesse e mais - Millenium25 abril 2025

Mapa interativo de Elden Ring mostra localização de itens, NPCs, pontos de interesse e mais - Millenium25 abril 2025 -

Garry's Mod Murder - Restaurante da Morte, Mundo Zelda e Boneca do Mal!25 abril 2025

Garry's Mod Murder - Restaurante da Morte, Mundo Zelda e Boneca do Mal!25 abril 2025 -

Se Tiver um Anime do Filho do Boruto, Como seria a historia?25 abril 2025

-

Lelouch Lamperouge Chrome Themes - ThemeBeta25 abril 2025

Lelouch Lamperouge Chrome Themes - ThemeBeta25 abril 2025 -

![Stable aqueous formulations of adalimumab Patent Grant Manning , et al. Sept [Coherus Biosciences, Inc.]](https://uspto.report/patent/grant/10780163/US10780163-20200922-D00001.png) Stable aqueous formulations of adalimumab Patent Grant Manning , et al. Sept [Coherus Biosciences, Inc.]25 abril 2025

Stable aqueous formulations of adalimumab Patent Grant Manning , et al. Sept [Coherus Biosciences, Inc.]25 abril 2025 -

Requisitos mínimos e recomendados de Call of Duty Vanguard são25 abril 2025

Requisitos mínimos e recomendados de Call of Duty Vanguard são25 abril 2025 -

STREET FIGHTER V: M. BISON História individual25 abril 2025

STREET FIGHTER V: M. BISON História individual25 abril 2025 -

Been seeing a few tier lists; I ranked the Ultra Beasts : r/MandJTV25 abril 2025

Been seeing a few tier lists; I ranked the Ultra Beasts : r/MandJTV25 abril 2025 -

DUBLADORES DE IN ANOTHER WORLD WITH MY SMARTPHONE!!25 abril 2025

DUBLADORES DE IN ANOTHER WORLD WITH MY SMARTPHONE!!25 abril 2025